Unit PC Gear

Reliabiliti

● Perumahan: paeh-hal alloy aluminium, aranjeunna dijieun ku puseur machining horizontal di hiji-waktos-molding, ensures akurasi sarta kasabaran bentuk jeung posisi

● The gears anu gear permukaan teuas, dijieunna tina alloy kualitas luhur, diolah ku hardening permukaan, sarta dihasilkeun ku-precision tinggi mesin grinding

| PCGEARUNITS | |||||||||||

| RV | PC063 | PC071 | PC080 | PC090 | |||||||

| IEC | 105/11 | 105/14 | 120/14 | 120/19 | 160/19 | 160/24 | 160/28 | 160/19 | 160/24 | 160/28 | |

| abdi = 2.93 | abdi = 2.93 | abdi = 2.94 | abdi = 2.94 | abdi=3 | abdi=3 | abdi=3 | abdi = 2.45 | abdi = 2.45 | abdi = 2.45 | ||

| 040 | 25 | ||||||||||

| 30 | |||||||||||

| 40 | |||||||||||

| 50 | |||||||||||

| 60 | |||||||||||

| 80 | |||||||||||

| 100 | |||||||||||

| 050 | 25 | ||||||||||

| 30 | |||||||||||

| 40 | |||||||||||

| 50 | |||||||||||

| 60 | |||||||||||

| 80 | |||||||||||

| 100 | |||||||||||

| 063 | 25 | ||||||||||

| 30 | |||||||||||

| 40 | |||||||||||

| 50 | |||||||||||

| 60 | |||||||||||

| 80 | |||||||||||

| 100 | |||||||||||

| 075 | 25 | ||||||||||

| 30 | |||||||||||

| 40 | |||||||||||

| 50 | |||||||||||

| 60 | |||||||||||

| 80 | |||||||||||

| 100 | |||||||||||

| 090 | 25 | ||||||||||

| 30 | |||||||||||

| 40 | |||||||||||

| 50 | |||||||||||

| 60 | |||||||||||

| 80 | |||||||||||

| 100 | |||||||||||

| 110 | 25 | ||||||||||

| 30 | |||||||||||

| 40 | |||||||||||

| 50 | |||||||||||

| 60 | |||||||||||

| 80 | |||||||||||

| 100 | |||||||||||

| 130 | 25 | ||||||||||

| 30 | |||||||||||

| 40 | |||||||||||

| 50 | |||||||||||

| 60 | |||||||||||

| 80 | |||||||||||

| 100 | |||||||||||

Rincian produk

Garis produk kami kalebet opat jinis pangurangan, masing-masing gaduh spésifikasi dasar anu béda - 063, 071, 080 sareng 090. Ieu ngamungkinkeun para nasabah urang milih réduksi anu paling cocog sareng kabutuhan unikna, mastikeun efisiensi sareng kinerja optimal.

Dina hal konsumsi kakuatan, réduksi kami nyayogikeun kakuatan ti 0.09 dugi ka 1.5kW. Kalenturan ieu ngamungkinkeun anjeun milih tingkat kakuatan anu cocog pikeun aplikasi khusus anjeun sareng ngahindarkeun runtah énergi anu teu perlu.

Salaku tambahan, réduksi kami gaduh torsi kaluaran maksimal 24Nm, mastikeun aranjeunna tiasa ngadamel tugas anu paling nuntut. Naha éta tugas beurat atanapi aplikasi anu gancang, pangurangan urang naék kana tantangan kalayan gampang.

Anu ngabédakeun pangurangan kami nyaéta kasaluyuanna sareng sistem RV, nambihan fleksibilitas tambahan kana solusi pangiriman listrik anjeun. Reducer kami ngahijikeun mulus sareng sistem RV, nawiskeun rasio laju anu lega tina 2,45 dugi ka 300. Ieu ngamungkinkeun anjeun pikeun gampang ngahontal kagancangan sareng akurasi anu anjeun peryogikeun dina operasi anjeun.

Lamun datang ka reliabiliti, reducers kami téh kadua pikeun euweuh. Kabinet dijieunna tina alloy aluminium kualitas luhur, nu boga durability alus teuing jeung teu karat. Pamakéan puseur machining nangtung salila prosés manufaktur ensures precision tinggi, ngajaga bentuk tightest jeung posisi tolerances.

Pikeun ningkatkeun deui réliabilitas sareng daya tahan, gears dina réduksi kami didamel tina bahan alloy anu berkualitas tinggi. Sajaba ti éta, gears anu case-hardened tur taliti machined maké coét gear-precision tinggi. Hasilna mangrupikeun alat anu bermuka keras anu tiasa nahan kaayaan operasi anu paling parah.

Pondokna, pangurangan kami mangrupikeun conto efisiensi, réliabilitas sareng daya tahan. Kasaluyuan seamless maranéhanana jeung sistem RV, rentang rasio lega tur konstruksi terjal ngajadikeun eta pilihan pamungkas pikeun solusi transmisi kakuatan. Tong kompromi dina pagelaran - pilih pangurangan kami sareng alami bédana langsung.

Aplikasi

Feeders screw pikeun bahan hampang, kipas, garis assembly, belts conveyor pikeun bahan lampu, mixers leutik, lifts, mesin beberesih, fillers, mesin kontrol.

Alat pungkal, feeders mesin woodworking, lifts barang, balancers, mesin threading, mixers sedeng, belts conveyor pikeun bahan beurat, winches, panto ngageser, scrapers pupuk, mesin packing, mixers beton, mékanisme bango, cutters panggilingan, mesin tilepan, pompa gear.

Mixers pikeun bahan beurat, shears, presses, centrifuges, rotasi ngarojong, winches jeung lifts pikeun bahan beurat, grinding lathes, gilinding batu, lift LIPI, mesin pangeboran, palu gilinding, cam presses, mesin tilepan, turntables, tumbling tong, vibrator, shredders. .

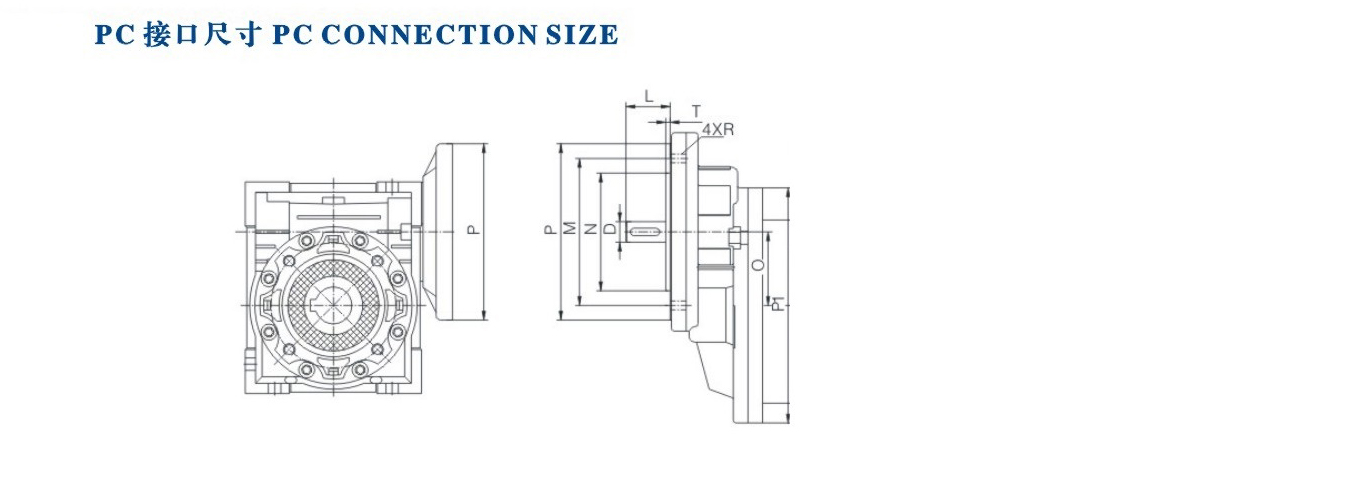

| TIPE | D (k6) | N(j6) | M | O | P | P1 | R | T | L |

| PC063 | 11 (14) | 70 | 85 | 40 | 105 | 140(63B5) | m6 | 3 | 23 |

| PC071 | 14 (19) | 80 | 100 | 48 | 120 | 160(71B5) | m6 | 30 | |

| PC080 | 19 (2428) | 110 | 130 | 62 | 160 | 200(80B5) | m8 | 40 | |

| PC090 | 24 (1928) | 110 | 130 | 62 | 160 | 200(90B5) | m8 | 50 |

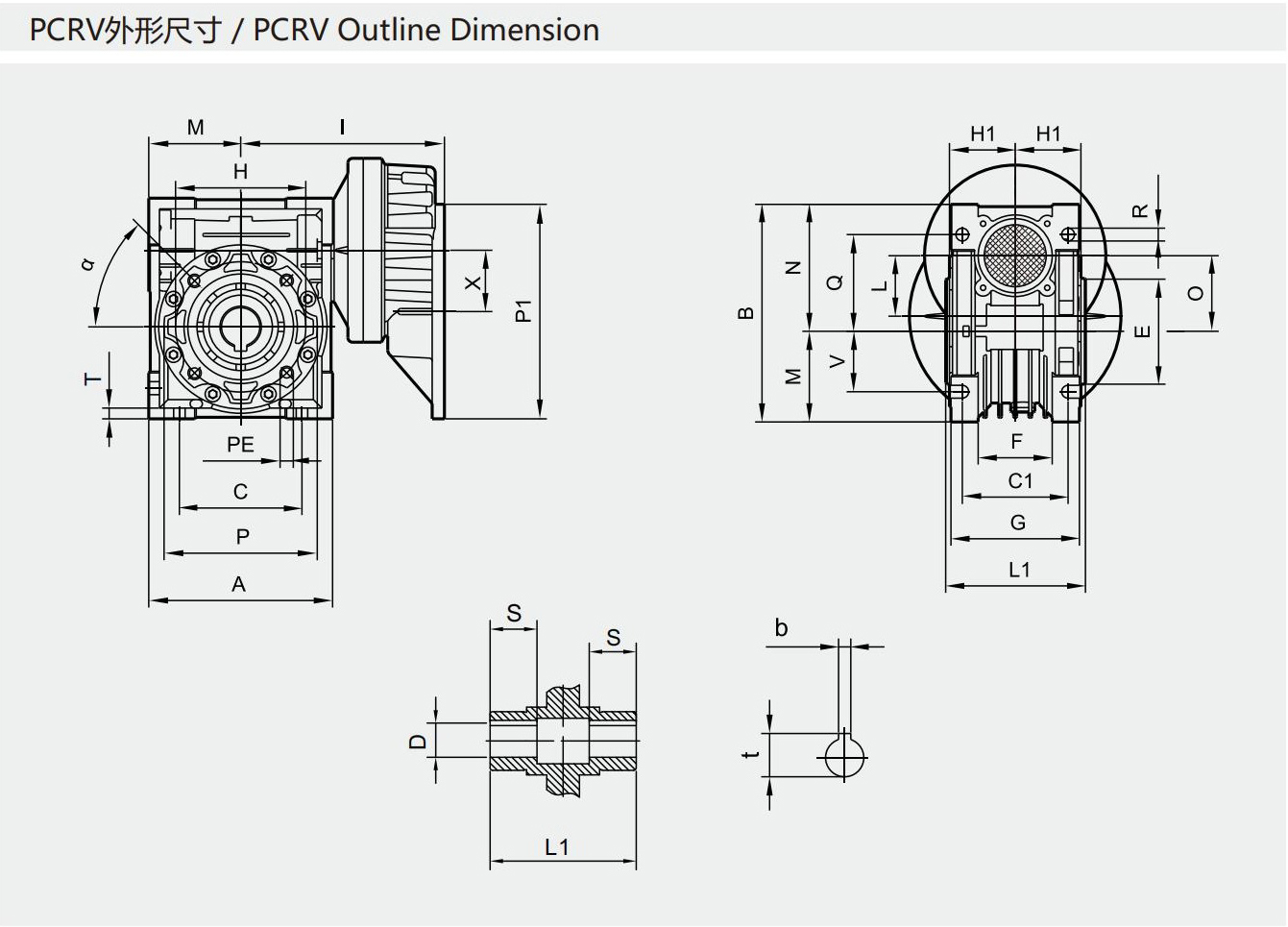

| PCRV | A | B | C | C1 | D(H7) | E (h8) | F | G | H | H1 | L1 | M | N | O | P | P1 | X | ||

| 063/040 | 100 | 121.5 | 70 | 60 | 18 (19) | 60 | 43 | 71 | 75 | 36.5 | 117 | 40 | 78 | 50 | 71.5 | 40 | 87 | 140 | 43 |

| 063/050 | 120 | 144 | 80 | 70 | 25 (24) | 70 | 49 | 85 | 85 | 43.5 | 127 | 40 | 92 | 60 | 84 | 50 | 100 | 140 | 43 |

| 063/063 | 144 | 174 | 100 | 85 | 25 (28) | 80 | 67 | 103 | 95 | 53 | 142 | 40 | 112 | 72 | 102 | 63 | 110 | 140 | 43 |

| 071/050 | 120 | 144 | 80 | 70 | 25 (24) | 70 | 49 | 85 | 85 | 43.5 | 137 | 50 | 92 | 60 | 84 | 50 | 100 | 160 | 54 |

| 071/063 | 144 | 174 | 100 | 85 | 25(28 | 80 | 67 | 103 | 95 | 53 | 152 | 50 | 112 | 72 | 102 | 63 | 110 | 160 | 54 |

| 071/075 | 172 | 205 | 120 | 90 | 28 (35) | 95 | 72 | 112 | 115 | 57 | 169.5 | 50 | 120 | 86 | 119 | 75 | 140 | 160 | 54 |

| 071/090 | 206 | 238 | 140 | 00 | 35 (38) | 110 | 74 | 130 | 130 | 67 | 186.6 | 50 | 140 | 103 | 135 | 90 | 160 | 160 | 54 |

| 080/075 | 172 | 205 | 120 | 90 | 28(35 | 95 | 72 | 12 | 115 | 57 | 186.5 | 63 | 120 | 86 | 119 | 75 | 140 | 200 | 66 |

| 080/090 | 206 | 238 | 140 | 100 | 35(38 | 110 | 74 | 130 | 130 | 67 | 203.5 | 63 | 140 | 103 | 135 | 90 | 160 | 200 | 66 |

| 080(090)/110 | 255 | 295 | 170 | 115 | 42 | 130 | - | 144 | 165 | 74 | 234 | 63 | 155 | 27.5 | 167.5 | 10 | 200 | 200 | 66 |

| 080(090)/130 | 293 | 335 | 200 | 120 | 45 | 180 | - | 155 | 215 | 81 | 253 | 63 | 170 | 147.5 | 87.5 | 30 | 250 | 200 | 66 |

| PCRV | Q | R | S | T | V | PE | b | t | α | Kg |

| 063/040 | 55 | 6.5 | 26 | 6.5 | 35 | M6x8(n=4) | 6 | 20.8(21.8) | 45° | 3.9 |

| 063/050 | 64 | 8.5 | 30 | 7 | 40 | M8x10(n=4) | 8 | 28.3(27.3) | 45° | 5.2 |

| 063/063 | 80 | 8.5 | 36 | 8 | 50 | M8x14(n=8) | 8 | 28.3(31.3) | 45° | 7.9 |

| 071/050 | 64 | 8.5 | 30 | 7 | 40 | M8x10(n=4) | 8 | 28.3(27.3) | 45° | 5.8 |

| 071/063 | 80 | 8.5 | 36 | 8 | 50 | M8x14(n=8) | 8 | 28.3(31.3) | 45° | 8.5 |

| 071/075 | 93 | 11 | 40 | 10 | 60 | M8x14(n=8) | 8 | 31.3(38.3) | 45° | 11.3 |

| 071/090 | 102 | 13 | 45 | 11 | 70 | M10x18(n=8) | 10 | 38.3(41.3) | 45° | 15.3 |

| 080/075 | 93 | 11 | 40 | 10 | 60 | M8x14(n=8) | 8(10) | 31.3(38.3) | 45° | 13.1 |

| 080/090 | 102 | 13 | 45 | 11 | 70 | M10x18(n=8) | 10 | 38.3(41.3) | 45° | 17.2 |

| 080(090)/110 | 125 | 14 | 50 | 14 | 85 | M10x18(n=8) | 12 | 45.3 | 45° | 44.5 |

| 080(090)/130 | 140 | 16 | 60 | 15 | 100 | M12x21(n=8) | 14 | 48.8 | 45° | 57.8 |