BAB Precision Planét Unit Gear

Reliabiliti

●Spiral gears comfiquration diadopsi kalawan babandingan Dursasana-ment sakumaha dua kali spur gears umum, fitur kaayaan ngajalankeun leuwih lemes, noise low, torsi kaluaran tinggi na backclearance low.

● Gears dijieunna tina logam alloy kalawan kualitas premium, dilarapkeun kalawan perlakuan karasa permukaan, grinded byhigh-precision coét, maturan hébat maké-resisting ciri sarta lalawanan dampak.

| Modél NO | Panggung | Babandingan | BAB042 | BAB060 | BAB060A | BAB090 | BAB 90A | BAB 115 | BAB 142 | BAB 180 | BAB 220 | |

| (Torsi Kaluaran Mominal Tzn) | Nm | 1 | 3 | 20 | 55 | - | 130 | - | 208 | 342 | 588 | 1140 |

| 4 | 19 | 50 | - | 140 | - | 290 | 542 | 1050 | 1700 | |||

| 5 | 22 | 60 | - | 16C | - | 330 | 650 | 1200 | 2000 | |||

| 6 | 20 | 55 | - | 150 | - | 310 | 600 | 1100 | 1900 | |||

| 7 | 19 | 50 | - | 14C | - | 300 | 550 | 1100 | 1800 | |||

| 8 | 17 | 45 | - | 120 | - | 260 | 500 | 1000 | 1600 | |||

| 9 | 14 | 40 | - | 100 | - | 230 | 450 | 900 | 1500 | |||

| 10 | 14 | 40 | - | 100 | - | 230 | 450 | 900 | 1500 | |||

| 2 | 15 | 20 | 55 | 55 | 130 | 130 | 208 | 342 | 588 | 1140 | ||

| 20 | 19 | 50 | 50 | 140 | 140 | 290 | 542 | 1050 | 1700 | |||

| 25 | 22 | 60 | 60 | 160 | 160 | 330 | 650 | 1200 | 2000 | |||

| 30 | 20 | 55 | 55 | 150 | 150 | 310 | 600 | 1100 | 1900 | |||

| 35 | 19 | 50 | 50 | 140 | 140 | 300 | 550 | 1100 | 1800 | |||

| 40 | 17 | 45 | 45 | 120 | 120 | 260 | 500 | 1000 | 1600 | |||

| 45 | 14 | 40 | 40 | 100 | 100 | 230 | 450 | 900 | 1500 | |||

| 50 | 22 | 60 | 60 | 160 | 160 | 330 | 650 | 1200 | 2000 | |||

| 60 | 20 | 55 | 55 | 150 | 150 | 310 | 600 | 1100 | 1900 | |||

| 70 | 19 | 50 | 50 | 140 | 140 | 300 | 550 | 1100 | 1800 | |||

| 80 | 17 | 45 | 45 | 120 | 120 | 260 | 500 | 1000 | 1600 | |||

| 90 | 14 | 40 | 40 | 10C | 10C | 230 | 450 | 900 | 1500 | |||

| 100 | 14 | 40 | 40 | 100 | 100 | 230 | 450 | 900 | 1500 | |||

| (Eureun Darurat Torsi Tznor | Nm | 1,2 | 3~100 | (3 Kali tina Mominal Output Torsi) | ||||||||

| (Laju Input Nominal Nin) | rpm | 1,2 | 3~100 | 5.000 | 5.000 | 5.000 | 4000 | 4000 | 4000 | 3000 | 3000 | 2000 |

| (Laju Input Nominal Nia) | rpm | 1,2 | 3~100 | 10.000 | 10.000 | 10.000 | 8000 | 8000 | 8000 | 6000 | 6000 | 4000 |

| (Micro Backlash PO) | arcmin | 1 | 3~10 | - | - | - | ≤1 | - | ≤1 | ≤1 | ≤1 | ≤1 |

| 2 | 15~100 | - | - | - | - | ≤3 | ≤3 | ≤3 | ≤3 | |||

| (Reduced Backlash P1) | arcmin | 1 | 3~10 | ≤3 | ≤3 | - | ≤3 | - | ≤3 | ≤3 | ≤3 | S3 |

| 2 | 15~100 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | S5 | ≤5 | ||

| (Standard Backlash P2) | arcmin | 1 | 3~10 | ≤5 | ≤5 | ≤5 | - | ≤5 | ≤5 | ≤5 | ≤5 | |

| 2 | 15~100 | ≤7 | ≤7 | ≤7 | ≤7 | ≤7 | ≤7 | ≤7 | ≤7 | ≤7 | ||

| (Efisiensi) | % | 1 | S97% | |||||||||

| 2 | 15~100 | ≤94% | ||||||||||

| (Beurat) | kg | 1 | 3~10 | 0.6 | 1.3 | - | 3.7 | - | 7.8 | 14.5 | 29 | 48 |

| 2 | 15~100 | 0.8 | 1.5 | 1.9 | 4.1 | 5.3 | 9 | 17.5 | 33 | 60 | ||

| (Suhu Operasi) | ℃ | 1,2 | 3~100 | -10 ℃ ~ 90 ℃ | ||||||||

| (Lubrication) | 1.2 | Syntheticlubricationoils | ||||||||||

| (Gelar Perlindungan Gearbox) | 1,2 | IP65 | ||||||||||

| (Posisi Pasang) | 1,2 | 3~100 | Sadayana arah | |||||||||

| Noise (n1 = 3000rpm i = 10, Taya beban) | dB(A) | 1,2 | 3~100 | ≤56 | ≤58 | s60 | ≤60 | ≤63 | ≤63 | ≤65 | ≤67 | ≤70 |

Rincian produk

Ngenalkeun produk panganyarna kami, réduksi serbaguna sareng dipercaya! Dirancang pikeun nyumponan rupa-rupa syarat sareng nganteurkeun kinerja anu unggul, réduksi ieu dilengkepan spésifikasi sareng fitur anu canggih.

Aya tujuh spésifikasi anu béda pikeun dipilih, kalebet 042, 060, 090, 115, 142, 180 sareng 220. Konsumén sacara fleksibel tiasa milih réduksi anu paling cocog sareng kabutuhanna. Naha anjeun peryogi torsi anu luhur atanapi rasio pangurangan khusus, kami parantos katutupan.

Ngomongkeun prestasi, réduksi kami gaduh torsi kaluaran maksimal 2000Nm, mastikeun kakuatan sareng efisiensi anu saé. Salaku tambahan, aranjeunna sayogi dina sababaraha rasio pangurangan tahap tunggal (ti 3 dugi ka 10), masihan anjeun pilihan kontrol sareng kustomisasi anu langkung ageung. Pikeun anu milarian tingkat réduksi maju, tingkat dual kami kalebet 15, 20, 25, 30, 35, 40, 45, 50, 60, 70, 80, 90 sareng 100.

Lamun datang ka reliabiliti, reducers kami bener unggul. Mékanisme panguranganna ngadopsi desain gear hélik, sareng laju meshing huntuna langkung ti dua kali tina gear spur biasa. Ieu ngakibatkeun operasi lemes, tingkat noise lemah sareng torsi kaluaran tinggi. Salaku tambahan, pangurangan kami dirarancang kalayan fitur clearance anu rendah pikeun mastikeun kinerja anu mulus sareng tepat.

Pikeun mastikeun daya tahan sareng umur jasa, gears di reducer kami didamel tina bahan alloy anu berkualitas tinggi. Gears ieu kasus-hardened tur taliti machined maké grinders gear-precision tinggi, hasilna maké-tahan, dampak-tahan jeung bagian tangguh. Ieu mastikeun réduksi urang tiasa tahan kana aplikasi sareng lingkungan anu paling nuntut.

Pondokna, pangurangan kami nawiskeun kinerja anu teu aya tandingan, réliabilitas sareng daya tahan. Rupa-rupa spésifikasina, kamampuan torsi anu luhur sareng babandingan pangurangan maju ngajantenkeun aranjeunna cocog pikeun sababaraha industri sareng aplikasi. Dicadangkeun ku komitmen kami pikeun kualitas sareng kapuasan pelanggan, kami yakin yén pangurangan kami bakal ngaleuwihan ekspektasi anjeun sareng nyayogikeun kinerja anu optimal pikeun kabutuhan khusus anjeun. Ngalaman kakuatan sareng katepatan tina réduksi kami ayeuna!

Aplikasi

1. widang Aerospace

2. Industri médis

3. Robot industri, Automation Industri, alat mesin CNC industri manufaktur industri otomotif, percetakan, tatanén, industri pangan, rékayasa panyalindungan lingkungan, industri logistik gudang.

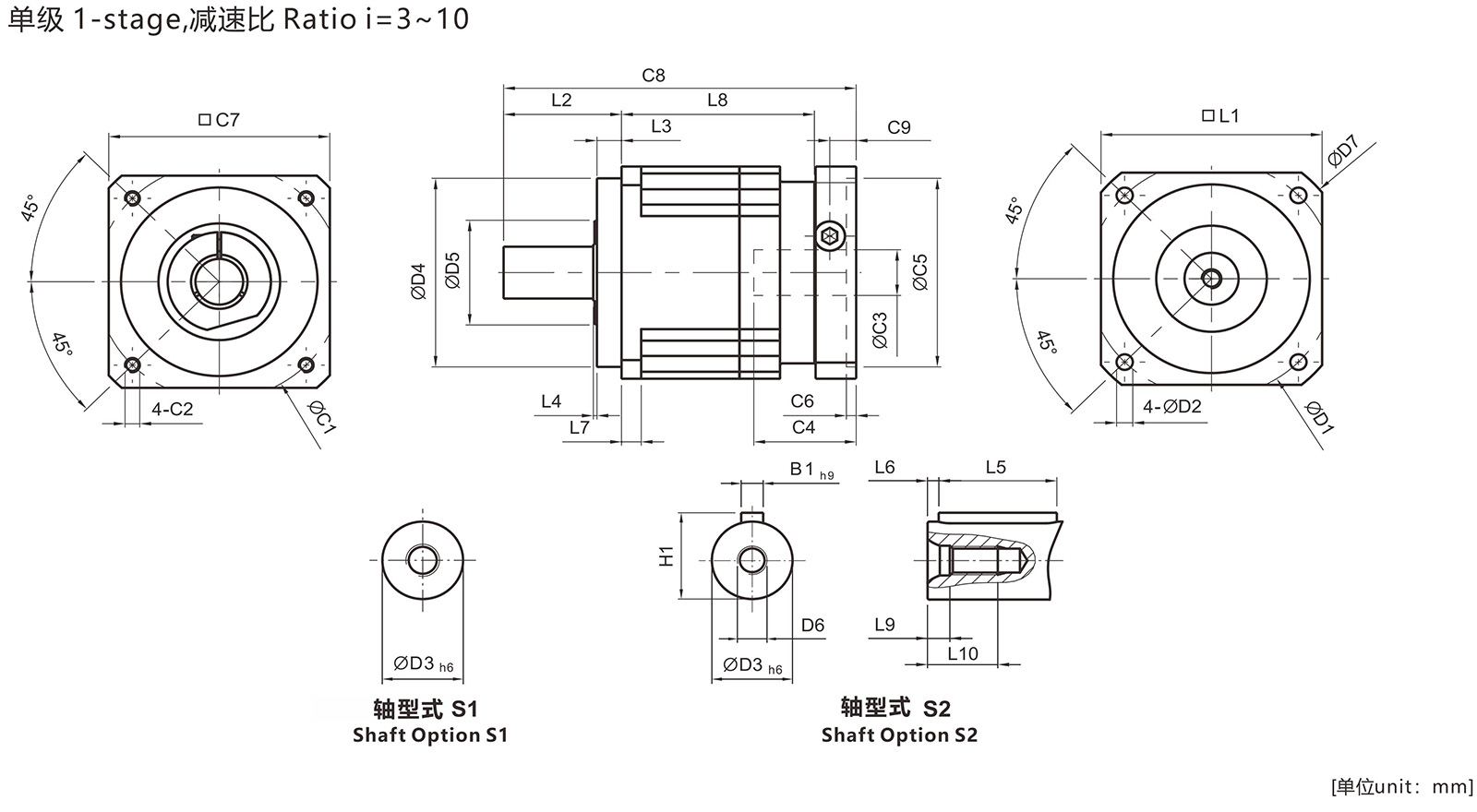

| Diménsi | BAB042 | BAB060 | BAB090 | BAB 115 | BAB 142 | BAB 180 | BAB 220 |

| D1 | 50 | 70 | 100 | 130 | 165 | 215 | 250 |

| D2 | 3.4 | 5.5 | 6.6 | 9 | 11 | 13 | 17 |

| D3h6 | 13 | 16 | 22 | 32 | 40 | 55 | 75 |

| D4g6 | 35 | 50 | 80 | 110 | 130 | 160 | 180 |

| D5 | 22 | 45 | 65 | 95 | 75 | 95 | 115 |

| D6 | M4x0.7P | M5 × 0,8P | M8× 1,25P | M12×1,75P | M16×2P | M20 x 2.5P | M20 x 2.5P |

| D7 | 56 | 80 | 116 | 152 | 185 | 240 | 292 |

| L1 | 42 | 60 | 90 | 115 | 142 | 180 | 220 |

| L2 | 26 | 37 | 48 | 65 | 97 | 105 | 138 |

| L3 | 5.5 | 7 | 10 | 12 | 15 | 20 | 30 |

| L4 | 1 | 1.5 | 1.5 | 2 | 3 | 3 | 3 |

| L5 | 16 | 25 | 32 | 40 | 65 | 70 | 90 |

| L6 | 2 | 2 | 3 | 5 | 5 | 6 | 7 |

| L7 | 4 | 6 | 8 | 10 | 12 | 15 | 20 |

| L8 | 31 | 61 | 78.5 | 102 | 104 | 154 | 163.5 |

| L9 | 4.5 | 4.8 | 7.2 | 10 | 12 | 15 | 15 |

| L10 | 10 | 12.5 | 19 | 28 | 36 | 43 | 42 |

| C11 | 46 | 70 | 100 | 130 | 165 | 215 | 235 |

| C21 | M4x0.7Px10 | M5x0.8Px12 | M6x1Px12 | M8X1.25Px25 | M10x1·5Px25 | M12 x 1.75 P x 28 | M12 x 1.75 P x 28 |

| C31 G7 | ≤11/≤122 | ≤14/≤16² | ≤19/≤24 | ≤32 | ≤38 | ≤48 | ≤55 |

| C41 | 25 | 34 | 40 | 50 | 60 | 85 | 116 |

| C51 G7 | 30 | 50 | 80 | 110 | 130 | 180 | 200 |

| C61 | 3.5 | 4 | 6 | 5 | 6 | 6 | 6 |

| C71 | 42 | 60 | 90 | 115 | 142 | 190 | 220 |

| C81 | 86.5 | 117 | 143.5 | 186.5 | 239 | 288 | 364.5 |

| C91 | 8.75 | 13.5 | 10.75 | 13 | 15 | 20.75 | 53 |

| B1h9 | 5 | 5 | 6 | 10 | 12 | 16 | 20 |

| H1 | 15 | 18 | 24.5 | 35 | 43 | 59 | 79.5 |

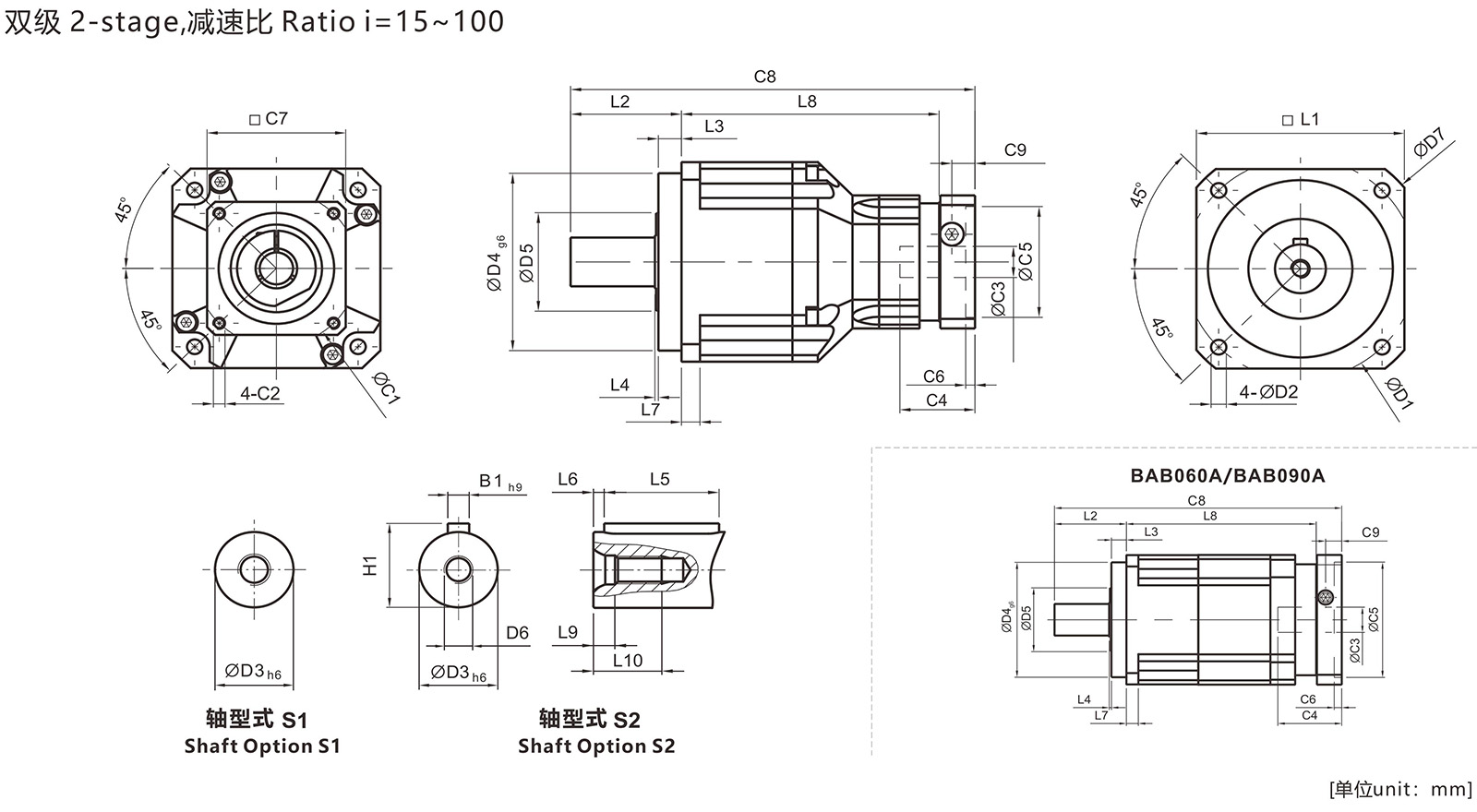

| Diménsi | BAB042 | BAB060 | BAB060A | BAB090 | BAB090A | BAB 115 | BAB 142 | BAB 180 | BAB 220 | |

| D1 | 50 | 70 | 100 | 130 | 165 | 215 | 250 | |||

| D2 | 3.4 | 5.5 | 6.6 | 9 | 11 | 13 | 17 | |||

| D3h6 | 13 | 16 | 22 | 32 | 40 | 55 | 75 | |||

| D4g6 | 35 | 50 | 80 | 110 | 130 | 160 | 180 | |||

| D5 | 22 | 45 | 65 | 95 | 75 | 95 | 115 | |||

| D6 | M4x0.7P | M5 × 0,8P | M8× 1,25P | M12×1,75P | M16×2P | M20 x 2.5P | M20 x 2.5P | |||

| D7 | 56 | 80 | 116 | 152 | 185 | 240 | 292 | |||

| L1 | 42 | 60 | 90 | 115 | 142 | 180 | 220 | |||

| L2 | 26 | 37 | 48 | 65 | 97 | 105 | 138 | |||

| L3 | 5.5 | 7 | 10 | 12 | 15 | 20 | 30 | |||

| L4 | 1 | 1.5 | 1.5 | 2 | 3 | 3 | 3 | |||

| L5 | 16 | 25 | 32 | 40 | 65 | 70 | 90 | |||

| L6 | 2 | 2 | 3 | 5 | 5 | 6 | 7 | |||

| L7 | 4 | 6 | 8 | 10 | 12 | 15 | 20 | |||

| L8 | 58.5 | 72 | 98 | 111.5 | 126.5 | 143.5 | 176 | 209.5 | 248 | |

| L9 | 4.5 | 4.8 | 7.2 | 10 | 12 | 15 | 15 | |||

| L10 | 10 | 12.5 | 19 | 28 | 36 | 42 | 42 | |||

| C11 | 46 | 46 | 70 | 70 | 100 | 100 | 130 | 165 | 215 | |

| C21 | M4x0.7Px10 | M4x0.7Px10 | M5x0.8Px12 | M5x0.8Px12 | M6x1Px12 | M6x1Px12 | M8 x 1,25 P x 25 | M10 x 1,5 P x 28 | M12 x 1.75 P x 28 | |

| C31 G7 | ≤11/≤12 | ≤11/≤12 | ≤14/≤16 | ≤14/15.875/≤16 | ≤19/≤24 | ≤19/≤24 | ≤32 | ≤38 | ≤48 | |

| C41 | 25 | 25 | 34 | 34 | 40 | 40 | 50 | 60 | 85 | |

| C51 G7 | 30 | 30 | 50 | 50 | 80 | 80 | 110 | 130 | 180 | |

| C61 | 3.5 | 3.5 | 4 | 6 | 4 | 4 | 5 | 6 | 6 | |

| C71 | 42 | 42 | 60 | 60 | 90 | 90 | 115 | 142 | 190 | |

| C81 | 114 | 138.5 | 154 | 178.5 | 191.5 | 225.5 | 292.5 | 337 | 415 | |

| C91 | 8.75 | 8.75 | 13.5 | 13.5 | 10.75 | 10.75 | 13 | 15 | 20.75 | |

| B1h9 | 5 | 5 | 6 | 10 | 12 | 16 | 20 | |||

| H1 | 15 | 18 | 24.5 | 35 | 43 | 59 | 79.5 | |||